The foremost theory on control valves and instrumentation

Generally, valves are devices that regulates and control the flow of a fluid either by partially opening,fully opening or closing of the valve disc.

Control valves which is the focus are valves that regulates the flow of fluid through the signals as directed from the sensors.Control valves can either be operated through electrical, pnuematic or hydraulic actuators.Control valves are classified according to;

- Action; air to open and air to close

- Flow characteristics; ideal characteristics and installed or effective characteristics

- Numbers of plugs; single seating plug and double seating plug

Based on Action

These are controls valves which are operated through pneumatic actuators to fully open or close the valve when air supply fails based on the need of the process.

https://instrumentationtools.com/wp-content/uploads/2016/10/instrumentationtools.com_control-valve-operation.png

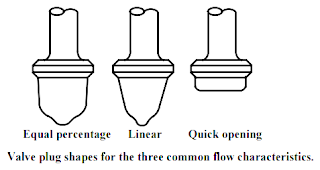

Based on flow characteristics

This shows the relationship between the control valve capacity and the movement of the stem. The ideal characteristics shows the relationship with constant pressure drop across the control valve while the effective characteristics show the overall pressure drop across the various installed valves in the process. Its also determined by the shape and size of the valve plug.

https://instrumentationtools.com/wp-content/uploads/2016/10/instrumentationtools.com_control-valve-plug-shapes.png

Based on numbers of plug

The numbers of plugs present determines the flow rate of the process. A single seating plug allows flow in one direction and it recommended for shut off system while the double seating plug allows flow in double direction through the upward and downward movement of the two plugs via the stem. The double seating plug is not suitable for a shutoff system due to the differential temperature expansion of the stem and the valve seat, however in a process that doesn't need a shutoff system, the double seating valve can be installed.

https://instrumentationtools.com/wp-content/uploads/2016/10/instrumentationtools.com_single-seated-and-double-seated-control-valves.png

- Solenoid valve

The solenoid valve which is a commonly used valve in the regulating of fluid, is an electromechanically operated device that is controlled by current through a solenoid. The valve consists of a solenoid and a moveable ferromagnetic core. The ferromagnetic core closes off the orifice when the circuit is opened. An electric current passes through the coil when the circuit is closed, hence causes a magnetic field to be created. The magnetic field generated exerts force on the core hence cause it to push towards the centre of the coil so that the orifice can be opened.

http://www.hvacspecialists.info/wp-content/uploads/2011/01/solenoid-valve-diagram.jpg

Comments

Post a Comment