THE LUBRICATION BASICS

Machines tends to fail or work below its required strength or capacity due to improper lubrication of the machine components. Many operators ignores the fact that friction exist thereby underestimating the importance of lubrication. Some do not know what lubrication means, its principle,the positives and negatives and why its necessary for it to be in check.

The techniques of using lubricants to reduce friction between surfaces is termed lubrication. This definition contains two main terms, lubricant and friction.

Understanding what friction is, will help us in the application of lubricants.

Friction is that which hinders a body from moving smoothly on the surface of another, a stationery and a moving part or two or moving parts. Friction has a role to play in machines but when it becomes excessive or when its not needed, damage will occur in the machine or its component. Effects like corrosion, overheating, wear and others have the possibility of occurring if its not lubricated.

To achieve reduced friction the lubricant which is the applied element must meet the following purposes.

Lubricant are of various types and functions

WHAT IF I DO NOT LUBRICATE

Inadequate lubrication often produces excessive heat thus bearing failure and the heat build up lowers the viscosity of the lubricant. The thickness of the fluid film that separates the bearing surfaces might be reduced which may lead to metal to metal contact and bearing failure.

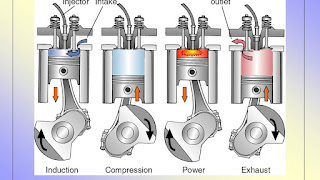

In internal combustion engines, lacks of lubrication causes metal to metal contact of the piston and the cylinder wall, improper sitting of the piston rings, over heating of valves,the connecting rod, cylinder head, cylinder wall, piston etc and as a result of this denotation occurs.

Note, proper lubrication enhances the life span of your bearings and machines, thus increased output efficiency. Time, money and manpower will be saved when proper lubrication are done.

Photo credit: www.ircm.com.pk ;me

credit:petroleum analysis laboratory unit, PTI,effurun

The techniques of using lubricants to reduce friction between surfaces is termed lubrication. This definition contains two main terms, lubricant and friction.

Understanding what friction is, will help us in the application of lubricants.

Friction is that which hinders a body from moving smoothly on the surface of another, a stationery and a moving part or two or moving parts. Friction has a role to play in machines but when it becomes excessive or when its not needed, damage will occur in the machine or its component. Effects like corrosion, overheating, wear and others have the possibility of occurring if its not lubricated.

To achieve reduced friction the lubricant which is the applied element must meet the following purposes.

- It most be able to resist temperature at the extremes(freeze & boiling point) to retains its viscosity index.

- The lubricant must be thick enough to seal and thin enough to minimize fluid friction

- Forming a sliding seal between the moving surface

- Cleaning function between the moving surface.

- It must not have a vanish tendency

Lubricant are of various types and functions

- Engine oil: lubricates the engine moving parts

- Grease: used for bearings

- Hydraulic oil: used for power steering of vehicles, excavators, industrial machineries etc.

- Brake fluid: used in hydraulic brake and clutches

- Transformer oil: used in oil filled transformers

- Soluble oil: used in vehicles to regulate the boiling and freezing point of water

- Solid lubricant(graphite)

SYSTEMS OF LUBRICATION

- Ring or lubricating disc lubrication

- Drip lubrication

- Force lubrication

- Splash lubrication

RING OR LUBRICATING DISC LUBRICATION

This method is used to lubricate plain bearings. The oil is lifted from the reservoir by the oil ring and on to the shaft which carries the oil to the bearings.

DRIP LUBRICATION

This method of lubrication which is also referred to as gravity feed lubrication is for light viscosity oil that flows to the bearing surfaces by the force of gravity.

FORCE LUBRICATION

This also called pressurized lubrication is carried out through an oil pump which provide the pressure and flow of oil to the bearing surfaces. It draws the oil through a strainer and a suction line, then forces it under pressure to the bearings. The oil circulates around the bearings then returns through the return line to the sump. This system can be used for the removal of heat from the bearing.

SPLASH LUBRICATION OR OIL BATH

This method of lubrication is used to lubricate gears and bearings inside machine housings. The oil sticks to the moving parts and its then splashed and thrown onto other surfaces above the oil level.

LUBRICATION PROBLEMS AND REMEDY

High oil temperature are caused by: lugged oil cooler, defective oil pump, abnormal engine jacket temperature

These defects can be corrected by cleaning the oil cooler with air pressure or steam. The damaged oil pump should be changed, and trace the cooling system components for forestall solution.

while LOW OIL TEMPERATURE are caused by low oil level or high aeration in the crank case, defective oil pump, plugged oil strainer, diluted or contaminated lubricant in the crank case and stocked oil pump relieved valved.

These defect can be corrected by checking for oil licks,rectify them and gauge the oil. Repair or change relieve valve. Clean the strainer and also check the pump, if faulty repair.

Inadequate lubrication often produces excessive heat thus bearing failure and the heat build up lowers the viscosity of the lubricant. The thickness of the fluid film that separates the bearing surfaces might be reduced which may lead to metal to metal contact and bearing failure.

In internal combustion engines, lacks of lubrication causes metal to metal contact of the piston and the cylinder wall, improper sitting of the piston rings, over heating of valves,the connecting rod, cylinder head, cylinder wall, piston etc and as a result of this denotation occurs.

Note, proper lubrication enhances the life span of your bearings and machines, thus increased output efficiency. Time, money and manpower will be saved when proper lubrication are done.

Photo credit: www.ircm.com.pk ;me

credit:petroleum analysis laboratory unit, PTI,effurun

Comments

Post a Comment